Recent Projects

618-10 Burial Ground Deactivation, Decommissioning and Remediation

One of the Department of Energy Hanford site’s most challenging cleanup projects was the 618-10 burial ground on the Hanford Site. The burial ground contained highly radioactive wastes that were generated by decades of activities developing and manufacturing reactor fuel and conducting laboratory plutonium production research.

Polestar played a significant role in the successful outcome and completion of this project from the very early planning stages of the project all the way through operations and final closure. Our subject matter experts performed a wide range of tasks from document development and tech editing, interpretation of drawings and specifications, strategic planning, authorization basis and USQ reviews, operational improvements, project engineering and general engineering which were critical to the success of the project.

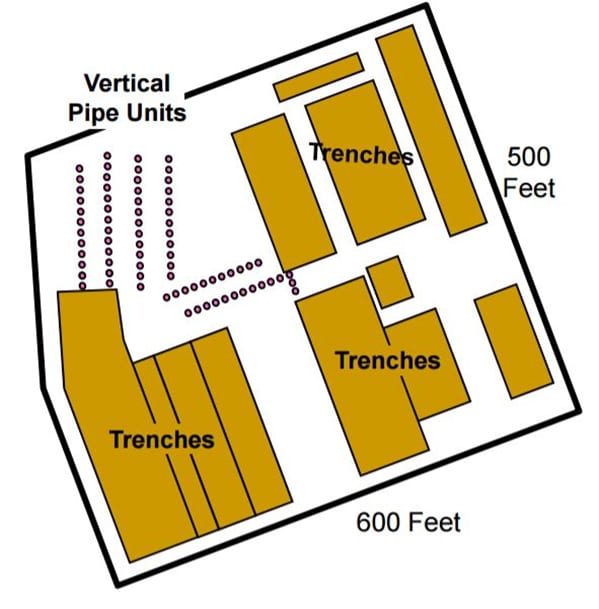

The 618-10 Burial Ground contained waste deposited in 94 Vertical Pipe Units constructed from various materials and 23 burial trenches containing a variety of waste containers. Total volume of waste in the trenches and VPUs exceeded 1 million cubic feet.

Historical records and waste inventories were incomplete and VPU’s and trenches contained variations of common contaminants of concerns and hazards from historical research facilities – but also include drums of black oxide, yellow cake uranium, pyrophoric turnings (in oil and reacting when unearthed) as well as a large number of concreted drums ranging to near zero to >50 Rem/hour.

Waste streams included Low Level Mixed Waste (LLMW), suspect Remote and Contact Handled Transuranic waste (RH-TRU and CH-TRU); with a potential of encountering Spent Nuclear Fuel (SNF).

618-10 Equipment Design, Construction, Training and Commissioning

Polestar provided experienced field engineering and management staff to the 618-10 project that included review of project design elements for constructability and operability, conceptual design of waste retrieval equipment, conceptual design of and contamination fixative equipment, oversight and testing at the manufacturing facility and acceptance testing responsibility once all the equipment was deemed ready for hot deployment on the project site. Polestar participated in the design of mock-up testing and led the on-site commissioning work of the auger and retrieval equipment including cold testing, physical installation in the field, procedure development and project readiness elements.

Polestar also developed, and led training efforts, qualification development, required reading and records management for the project.

618-10 Radiological Inventory

Polestar developed computer models, software tools, procedures, and trained a team in the art of extracting information from incomplete records, processing more than 10,000 shipment records to develop the source term contained in the burial ground. The effort concluded by documenting source term in several calculations. Polestar developed a novel tomography method to generate a 3D model of the radioactivity model of each VPU and rank the VPUs in order of inventory. This data was used to corroborate the data developed from the shipment records. The models were updated after the VPUs were potholed resulting an inventory reduction easing the operational controls and reducing cost and schedule. Polestar also developed a process to characterize the VPUs in-situ after auguring using dose rate measurements. This method was key in negotiations with regulators to replace planned characterization sampling with in-situ dose rate measurements. The cost, schedule and as low as reasonably achievable (ALARA) savings were substantial. Polestar also developed ALARA controls for each step in the VPU retrieval process.

618-10 Emergency Preparedness

Polestar authored and maintained the chemical and radiological Emergency Preparedness Hazards Assessments (EPHAs) emergency action levels and supporting calculations. Led and provided support for emergency drills.